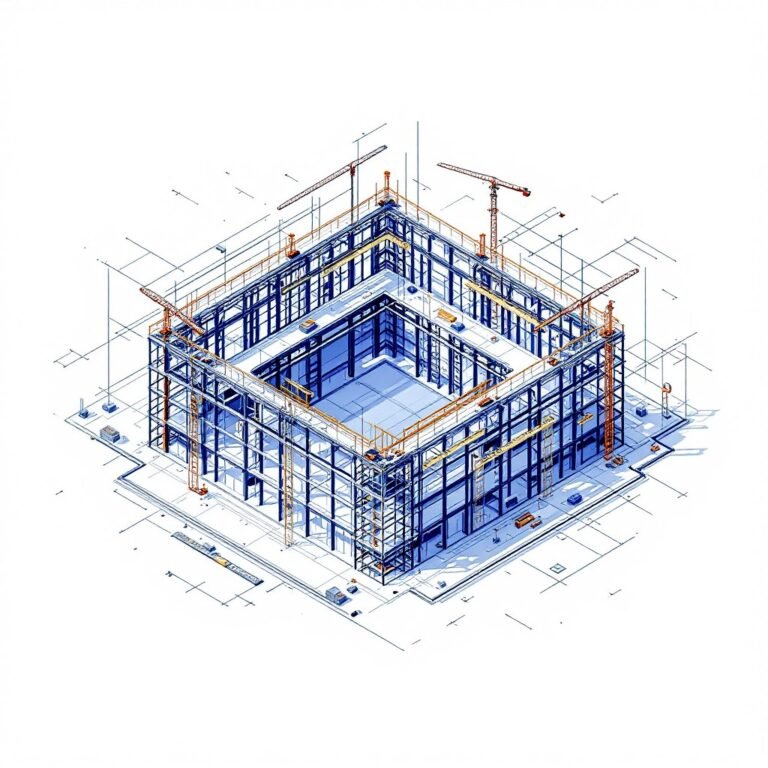

The Design Centre at Renny Strips Ltd is the nucleus of our engineering innovation, enabling the development of highly customized, project-specific solutions in scaffolding, formwork systems, steel structures, solar frameworks, livestock enclosures, and precision tubes. Our in-house design team undertakes a wide spectrum of functions, including custom component development, 3D CAD modeling, structural load and stress analysis, reverse engineering, die and fixture design, as well as product validation through prototyping and pilot runs.

Equipped with advanced design platforms such as AutoCAD, SolidWorks, and CAM tools for CNC/VMC programming, the centre ensures precise design execution and seamless integration with manufacturing. Our flexible design process allows us to modify material grades (ranging from 235 MPa to 460 MPa), wall thicknesses, diameters, profiles, finishes, and connection mechanisms—delivering fully engineered systems rather than off-the-shelf components. Close collaboration with in-house forging, fabrication, and tube-forming teams ensures rapid transition from concept to production, while custom-developed Poka-Yoke fixtures and gauges guarantee quality, consistency, and repeatability in every solution we deliver.